Getting Started with G-Code

Must Watch!

Getting Started with G-Code

Programming is a fundamental skill for all types of CNC machining, even as automation and new technology seem to be replacing programming tasks.

Every machinist still needs to understand how their programs and tools work.

Whether you're new to CNC programming and its most common language, g-code, or you've been writing code by scratch for years, CNC codes can still feel like a foreign language.

And to make things worse, every machine speaks a different dialect you have to understand.

Do you understand what they're saying? Here are the g-code basics you need to know to efficiently understand and write programs that produce high quality products.

What is G-Code?

G-code is a programming language for CNC that instructs machines where and how to move.

Most machines speak a different “dialect” of g-code, so the codes vary depending on type, make, and model.

Each machine comes with an instruction manual that shows that particular machine's code for a specific function.

G-code stands for “geometric code,” and follows some variation of the alpha numeric pattern:

N## G## X## Y## Z## F## S## T## M##

N: Line numberG: MotionX: Horizontal positionY: Vertical positionZ: DepthF: Feed rateS: Spindle speedT: Tool selectionM: Miscellaneous functionsI and J: Incremental center of an arcR: Radius of an arc

Alpha numeric codes are used for programming as they are a simple way to:

Define motion and function (G##)

Declare a position (X## Y## Z##)

Set a value (F## and/or S##)

Select an item (T##)

Switch something on and off (M##), such as coolant, spindles, indexing motion, axes locks, etc.

For example,

G01 X1 Y1 F20 T01 M03 S500

would generally indicate a linear feed move (G01) to the given XY position at feed rate of 20.

It is using Tool 1, and the spindle speed is 500.

Miscellaneous functions will vary from machine to machine, so in order to know what the m-code means, the machine's instruction manual will need to be referenced.

Machine Motion

Everything a machine can do is based on three basic types of motion:

Rapid move: a linear move to an XYZ position as fast as possible

Feed move: a linear move to an XYZ position at a defined feed rate

Circular move: a circular move at a defined feed rate

Every g-code tells the machine which variation of these basic motions to perform, and how to perform it.

X and Y are Cartesian coordinates for horizontal and vertical position, and Z represents the depth of the machine.

These alpha numerals will follow the motion/function command (G) to declare the position of the machine.

Next, F determines the feed rate (for feed moves or circular moves), while S determines the spindle speed.

T is used to select a tool.

Other alpha numerals used in programming might include I, J, and R, which have to do with arc centers and radii.

Miscellaneous Codes

The line of a program might also include m-codes, which are generally codes that tell a machine how to perform an action.

While not guaranteed to be the same across machines, some common, standard m-codes are:

M00: Program stop

M01: Optional program stop

M02: End of program

M03: Spindle on clockwise

M04: Spindle on counterclockwise

M05: Spindle stop

M06: Tool change

M08: Flood coolant on

M09: Flood coolant off

M30: End of program/return to start

M41: Spindle low gear range

M42: Spindle high gear range

Modality

Just like a light will stay on until it's turned off, g-code functions (on controllers that support modality) will remain active until they are deactivated by another code.

In other words, only one function can be active at any given time.

To deactivate a function, just select a new function.

For example, say a code begins with a linear rapid move at X1 Y1 (G00 X1 Y1).

If the next function is another linear rapid move, it is not necessary to write G00 again.

All that is needed on the next line of code is the new position (say, X2 Y2) because the modal condition is the same.

Then, to change the function to a linear feed (G01), programming G01 on the following line would deactivate the linear rapid move and activate the linear feed.

Once a condition is set, it stays active until it is turned off or another condition overrides it.

For example, say a code begins with a linear rapid move at X1 Y1 (G00 X1 Y1).

If the next function is another linear rapid move, it is not necessary to write G00 again.

All that is needed on the next line of code is the new position (say, X2 Y2) because the modal condition is the same.

Then, to change the function to a linear feed (G01), programming G01 on the following line would deactivate the linear rapid move and activate the linear feed.

Once a condition is set, it stays active until it is turned off or another condition overrides it.

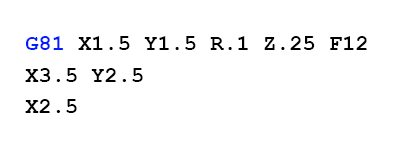

Canned Cycles

Canned cycles are a kind of modal condition that incorporate all the motions to complete a common task into one code.

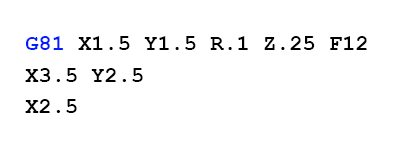

For example, oftentimes G81 is code for a basic drilling function.

In the case of basic drilling, the tool would have to be 1) moved to the starting point of the hole's location, 2) rapid to the clearance plane, 3) fed to the depth, and 4) rapid out.

That would be four lines of code in the program that would have to be repeated for every new drill position! With the canned cycle G81, only the hole locations need to be specified after activation.

Canned cycles like G81 significantly reduce the amount of code by incorporating multiple motions into one code.

For example, oftentimes G81 is code for a basic drilling function.

In the case of basic drilling, the tool would have to be 1) moved to the starting point of the hole's location, 2) rapid to the clearance plane, 3) fed to the depth, and 4) rapid out.

That would be four lines of code in the program that would have to be repeated for every new drill position! With the canned cycle G81, only the hole locations need to be specified after activation.

Canned cycles like G81 significantly reduce the amount of code by incorporating multiple motions into one code.

Some other common canned cycles exist for peck drilling, counter boring, and tapping.

Some other common canned cycles exist for peck drilling, counter boring, and tapping.

Modal Code Groups

Modal code groups allow there to be multiple codes on a single line, but there can only be one code from each group on a line.

This is because codes within a group will override each other.

The modal groups for g-codes are:

Group 1 (motion): G00, G01, G02, G03, G80, G81, G82, G84, G85, G86, G87, G88, G89

Group 2 (plane selection – XY, YZ, ZX): G17, G18, G19

Group 3 (absolute/incremental mode): G90, G91

Group 5 (feed rate mode): G93, G94

Group 6 (units – inches/millimeters): G20, G21

Group 7 (cutter radius compensation – CRC): G40, G41, G42

Group 8 (tool length offset – TLO): G43, G49

Group 10 (return mode in canned cycles): G98, G99

Group 12 (work coordinate system selection – WCSS): G54, G55, G56, G57, G58, G59)

Postprocessors

A postprocessor is a translator that translates the calculated image of a toolpath on your computer screen into the language for a machine control.

You can create a post processor by searching for a sample program that aligns closely with your machine, and then amending the program to precisely fit your machine.

Before you can do this, you'll need to know:

Get Started with G-Code

Ready to start using g-code to program your machines? Begin by reviewing your machine's unique coding chart.

Remember, every machine is a little different.

A Haas' code for a function might not be the same as an Anilam's code for that function.

You have to know which codes your specific machine uses for the tasks you want it to perform.

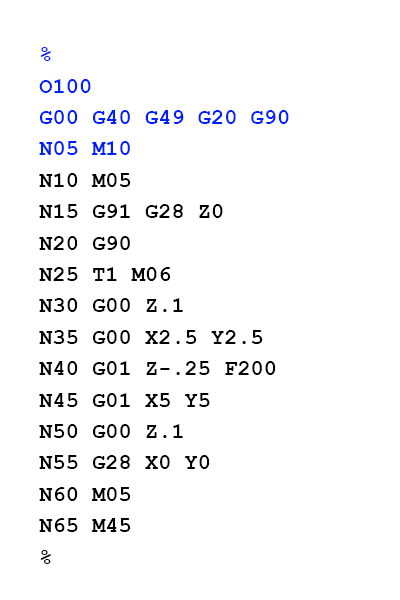

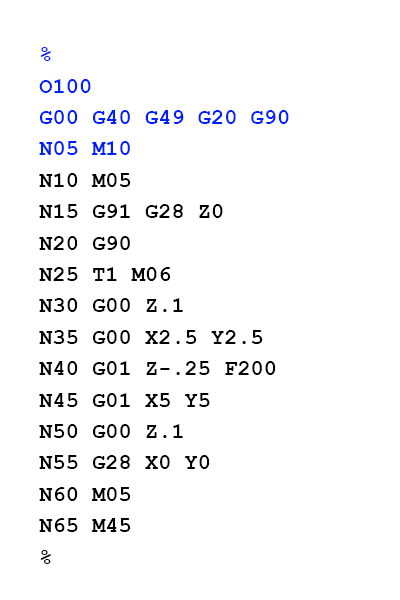

The program will often start with an initialization code (%), followed by a program number.

Then, there will be a line of safety codes.

Next will be a line for tool change.

This puts the appropriate tool in the machine and set the speed to be used.

The bulk of the program will then be the machine movements and positioning.

If using line numbering, it's a good idea to name each line in increments of at least five.

This way, if you need to add lines of code later, the lines will still be labelled in order.

When you've finished programming your g-code, you'll typically end the program with a series of functions that stop and reset the machine so it's ready for the next time.

G-Code Tips to Note

Some machines and controllers ignore spaces.

G01 X1 Y1 Z1 might mean the same thing as G01 X1Y1Z1.

The Z-axis is positive in the up direction.

Z1 will bring the tool up, while Z-1 will bring the tool down.

Your machine's g-code dialect will specify if a leading zero is necessary (as in G01, as opposed to G1).

The dialect will also determine if decimal points are always necessary (ex. G01 X1. Y1. Z0.5)

It's a good idea to run the sample programs that come in your machine manual before you try to run a big program.

Oftentimes, the sample programs do not work and you will need to note the issues and set your own benchmarks.

When used correctly, g-codes are an invaluable tool for CNC machinists, allowing you to take full advantage of your machine's capabilities.

And integrated CAM solutions continue to streamline the CNC coding process, so you don't have to program parts by hand using g-codes.

Producing high quality parts has never been faster.

G-code shouldn't be “all Greek” to you.

Even as automatic coding and other manufacturing advancements take shape, understanding CNC language will bridge the manufacturing borders that have been holding you back, helping you make the best products possible.

CNC G codes, M codes

Common G codes and M codes for CNC

Not all codes are available on all controls, and some controls have other codes.

See your machine manual for detailed explanations.

CNC G codes

Code Category Function Notes

G00 Motion Move in a straight line at rapids speed. XYZ of endpoint

G00 - Positioning at rapid speed; Mill and Lathe

G01 Motion Move in a straight line at last speed commanded by a (F)eedrate XYZ of endpoint

G01 - Linear interpolation (machining a straight line); Mill and Lathe

G02 Motion Clockwise circular arc at (F)eedrate XYZ of endpoint IJK relative to center R for radius

G02 - Circular interpolation clockwise (machining arcs); Mill and Lathe

G03 Motion Counter-clockwise circular arc at (F)eedrate XYZ of endpoint IJK relative to center R for radius

G03 - Circular interpolation, counter clockwise; Mill and Lathe

G04 Motion Dwell: Stop for a specified time. P for milliseconds X for seconds

G04 - Mill and Lathe, Dwell

G05 Motion FADAL Non-Modal Rapids

G09 Motion Exact stop check

G09 - Mill and Lathe, Exact stop

G10 Compensation Programmable parameter input

G10 - Setting offsets in the program; Mill and Lathe

G12 - Circular pocket milling, clockwise; Mill

G13 - Circular pocket milling, counterclockwise; Mill

G15 Coordinate Turn Polar Coordinates OFF, return to Cartesian Coordinates

G16 Coordinate Turn Polar Coordinates ON

G17 Coordinate Select X-Y plane

G17 - X-Y plane for arc machining; Mill and Lathe with live tooling

G18 Coordinate Select X-Z plane

G18 - Z-X plane for arc machining; Mill and Lathe with live tooling

G19 Coordinate Select Y-Z plane

G19 - Z-Y plane for arc machining; Mill and Lathe with live tooling

G20 Coordinate Program coordinates are inches

G20 - Inch units; Mill and Lathe

G21 Coordinate Program coordinates are mm

G21 - Metric units; Mill and Lathe

G27 Motion Reference point return check

G27 - Reference return check; Mill and Lathe

G28 Motion Return to home position

G28 - Automatic return through reference point; Mill and Lathe

G29 Motion Return from the reference position

G29 - Move to location through reference point; Mill and Lathe (slightly different for each machine)

G30 Motion Return to the 2nd, 3rd, and 4th reference point

G31 - Skip function; Mill and Lathe

G32 Canned Constant lead threading (like G01 synchronized with spindle)

G32 - Thread cutting; Lathe

G33 - Thread cutting; Mill

G40 Compensation Tool cutter compensation off (radius comp.)

G40 - Cancel diameter offset; Mill. Cancel tool nose offset; Lathe

G41 Compensation Tool cutter compensation left (radius comp.)

G41 - Cutter compensation left; Mill. Tool nose radius compensation left; Lathe

G42 Compensation Tool cutter compensation right (radius comp.)

G42 - Cutter compensation right; Mill. Tool nose radius compensation right; Lathe

G43 Compensation Apply tool length compensation (plus)

G43 - Tool length compensation; Mill

G44 Compensation Apply tool length compensation (minus)

G44 - Tool length compensation cancel; Mill (sometimes G49)

G49 Compensation Tool length compensation cancel

G50 Compensation Reset all scale factors to 1.0

G50 - Set coordinate system and maximum RPM; Lathe

G51 Compensation Turn on scale factors

G52 Coordinate Local workshift for all coordinate systems: add XYZ offsets

G52 - Local coordinate system setting; Mill and Lathe

G53 Coordinate Machine coordinate system (cancel work offsets)

G53 - Machine coordinate system setting; Mill and Lathe

G54 Coordinate Work coordinate system (1st Workpiece)

G54~G59 - Workpiece coordinate system settings #1 t0 #6; Mill and Lathe

G55 Coordinate Work coordinate system (2nd Workpiece)

G56 Coordinate Work coordinate system (3rd Workpiece)

G57 Coordinate Work coordinate system (4th Workpiece)

G58 Coordinate Work coordinate system (5th Workpiece)

G59 Coordinate Work coordinate system (6th Workpiece)

G61 Other Exact stop check mode

G61 - Exact stop check; Mill and Lathe

G62 Other Automatic corner override

G63 Other Tapping mode

G64 Other Best speed path

G65 Other Custom macro simple call

G65 - Custom macro call; Mill and Lathe

G68 Coordinate Coordinate System Rotation

G69 Coordinate Cancel Coordinate System Rotation

G70 - Finish cycle; Lathe

G71 - Rough turning cycle; Lathe

G72 - Rough facing cycle; Lathe

G73 Canned High speed drilling cycle (small retract)

G73 - Chip break drilling cycle; Mill

G73 - Irregular rough turning cycle; Lathe

G74 Canned Left hand tapping cycle

G74 - Face grooving or chip break drilling; Lathe

G74 - Left hand tapping; Mill

G75 - OD groove pecking; Lathe

G76 Canned Fine boring cyle

G76 - Fine boring cycle; Mill

G76 - Threading cycle; Lathe

G80 Canned Cancel canned cycle

G80 - Cancel cycles; Mill and Lathe

G81 Canned Simple drilling cycle

G81 - Drill cycle; Mill and Lathe

G82 Canned Drilling cycle with dwell (counterboring)

G82 - Drill cycle with dwell; Mill

G83 Canned Peck drilling cycle (full retract),Peck drilling cycle; Mill

G84 Canned Tapping cycle; Mill and Lathe

G85 Canned Boring canned cycle, no dwell, feed out, Bore in, bore out; Mill and Lathe

G86 Canned Boring canned cycle, spindle stop, rapid out, Bore in, rapid out; Mill and Lathe

G87 Canned Back boring canned cycle, Back boring cycle; Mill

G88 Canned Boring canned cycle, spindle stop, manual out

G89 Canned Boring canned cycle, dwell, feed out

G90 Coordinate Absolute programming of XYZ (type B and C systems), Absolute programming

G90.1 Coordinate Absolute programming IJK (type B and C systems)

G91 Coordinate Incremental programming of XYZ (type B and C systems), Incremental programming

G91.1 Coordinate Incremental programming IJK (type B and C systems)

G92 Coordinate Offset coordinate system and save parameters

G92 (alternate) Motion Clamp of maximum spindle speed S G92.1 Coordinate Cancel offset and zero parameters

G92 - Reposition origin point; Mill,Thread cutting cycle; Lathe

G92.2 Coordinate Cancel offset and retain parameters

G92.3 Coordinate Offset coordinate system with saved parameters

G94 Motion Units per minute feed mode. Units in inches or mm.,Per minute feed; Mill

G95 Motion Units per revolution feed mode. Units in inches or mm.,Per revolution feed; Mill

G96 Motion Constant surface speed control; Lathe

G97 Motion Cancel constant surface speed, Constant surface speed cancel

G98 Canned Return to initial Z plane after canned cycle, Per minute feed; Lathe

G99 Canned Return to initial R plane after canned cycle, Per revolution feed; Lathe

CNC M Codes

Code Category Function Notes

M00 Program Stop (non-optional); Mill and Lathe

M01 Optional Stop: Operator Selected to Enable, Optional program stop; Lathe and Mill

M02 End of Program, Program end; Lathe and Mill

M03 Spindle ON (CW Rotation); Lathe and Mill

M04 Spindle ON (CCW Rotation); Lathe and Mill

M05 Spindle Stop, Spindle off; Lathe and Mill

M06 Toolchange; Mill

M07 Mist Coolant ON

M08 Flood Coolant ON, Coolant on; Lathe and Mill

M09 Coolant off; Lathe and Mill

M10 Chuck or rotary table clamp; Lathe and Mill

M11 Chuck or rotary table clamp off; Lathe and Mill

M17 FADAL subroutine return

M19 Orient spindle; Lathe and Mill

M29 Rigid Tapping Mode on Fanuc Controls

M30 End of Program, Rewind and Reset Modes, Program end, return to start; Lathe and Mill

M97 Haas-Style Subprogram Call, Local sub-routine call; Lathe and Mill

M98 Sub-program call; Lathe and Mill

M99 Return from Subprogram, End of sub program; Lathe and Mill

For example, say a code begins with a linear rapid move at X1 Y1 (G00 X1 Y1).

If the next function is another linear rapid move, it is not necessary to write G00 again.

All that is needed on the next line of code is the new position (say, X2 Y2) because the modal condition is the same.

Then, to change the function to a linear feed (G01), programming G01 on the following line would deactivate the linear rapid move and activate the linear feed.

Once a condition is set, it stays active until it is turned off or another condition overrides it.

For example, say a code begins with a linear rapid move at X1 Y1 (G00 X1 Y1).

If the next function is another linear rapid move, it is not necessary to write G00 again.

All that is needed on the next line of code is the new position (say, X2 Y2) because the modal condition is the same.

Then, to change the function to a linear feed (G01), programming G01 on the following line would deactivate the linear rapid move and activate the linear feed.

Once a condition is set, it stays active until it is turned off or another condition overrides it.

For example, oftentimes G81 is code for a basic drilling function.

In the case of basic drilling, the tool would have to be 1) moved to the starting point of the hole's location, 2) rapid to the clearance plane, 3) fed to the depth, and 4) rapid out.

That would be four lines of code in the program that would have to be repeated for every new drill position! With the canned cycle G81, only the hole locations need to be specified after activation.

Canned cycles like G81 significantly reduce the amount of code by incorporating multiple motions into one code.

For example, oftentimes G81 is code for a basic drilling function.

In the case of basic drilling, the tool would have to be 1) moved to the starting point of the hole's location, 2) rapid to the clearance plane, 3) fed to the depth, and 4) rapid out.

That would be four lines of code in the program that would have to be repeated for every new drill position! With the canned cycle G81, only the hole locations need to be specified after activation.

Canned cycles like G81 significantly reduce the amount of code by incorporating multiple motions into one code.

Some other common canned cycles exist for peck drilling, counter boring, and tapping.

Some other common canned cycles exist for peck drilling, counter boring, and tapping.